The manufacturing industry is on the cusp of a groundbreaking transformation with the emergence of the industrial metaverse. This innovative concept integrates technologies like digital twins, IoT, AI, VR, and advanced networking to revolutionize collaboration, decision-making, and productivity.

By creating digital models of physical operations, organizations can enhance resilience and agility. However, fully realizing the potential of the industrial metaverse requires adaptability, collaboration, and a culture of innovation.

In this article, we explore the transformative power of the industrial metaverse and SAP's role in this dynamic landscape.

Digital twins can simulate different scenarios, enabling manufacturers to optimize processes, improve quality, and reduce downtime. Additionally, digital twins can be used throughout the product lifecycle, from design and development to maintenance and customer support.

This technology has the power to transform the manufacturing industry by increasing productivity, reducing costs, and enhancing overall competitiveness. As more companies embrace digital twins, we can expect to see significant advancements in manufacturing processes and outcomes.

Digital twins can simulate different scenarios, enabling manufacturers to optimize processes, improve quality, and reduce downtime. Additionally, digital twins can be used throughout the product lifecycle, from design and development to maintenance and customer support.

This technology has the power to transform the manufacturing industry by increasing productivity, reducing costs, and enhancing overall competitiveness. As more companies embrace digital twins, we can expect to see significant advancements in manufacturing processes and outcomes.

Through technologies like virtual reality (VR) and augmented reality (AR), participants can engage in collaborative discussions, brainstorming sessions, and problem-solving activities. These virtual workspaces offer a range of tools and features that facilitate efficient collaboration, such as real-time communication, file sharing, and interactive 3D models.

Additionally, advanced technologies like artificial intelligence (AI) and machine learning (ML) enable data-driven decision-making in the metaverse, leveraging analytics and predictive algorithms to inform strategic choices.

The integration of these technologies in the metaverse not only enhances productivity but also fosters innovation and creativity in the decision-making process.

Through technologies like virtual reality (VR) and augmented reality (AR), participants can engage in collaborative discussions, brainstorming sessions, and problem-solving activities. These virtual workspaces offer a range of tools and features that facilitate efficient collaboration, such as real-time communication, file sharing, and interactive 3D models.

Additionally, advanced technologies like artificial intelligence (AI) and machine learning (ML) enable data-driven decision-making in the metaverse, leveraging analytics and predictive algorithms to inform strategic choices.

The integration of these technologies in the metaverse not only enhances productivity but also fosters innovation and creativity in the decision-making process.

Additionally, advanced networks support immersive technologies like virtual reality and augmented reality, enabling remote collaboration and knowledge sharing.

With the ability to transmit large volumes of data quickly and securely, advanced networks are instrumental in unlocking the full potential of the industrial metaverse and driving the transformation of the manufacturing industry.

Additionally, advanced networks support immersive technologies like virtual reality and augmented reality, enabling remote collaboration and knowledge sharing.

With the ability to transmit large volumes of data quickly and securely, advanced networks are instrumental in unlocking the full potential of the industrial metaverse and driving the transformation of the manufacturing industry.

As organizations embrace the industrial metaverse, they must harness the power of technologies like digital twins, IoT, AI and ML, VR and AR, advanced 5G and 6G networks, and cloud and edge computing. These technologies enable organizations to create a digital model of their physical operations, facilitating better decision-making and resilience. Additionally, automation, robotics, and AI in the metaverse can revolutionize how operations work and make complex technologies more accessible.

However, successful transformation in the metaverse also relies on a proactive and adaptable approach, along with a culture of learning and innovation. Organizations must network and collaborate with experts, stay updated on technology trends, and continuously innovate to thrive in the metaverse.

As organizations embrace the industrial metaverse, they must harness the power of technologies like digital twins, IoT, AI and ML, VR and AR, advanced 5G and 6G networks, and cloud and edge computing. These technologies enable organizations to create a digital model of their physical operations, facilitating better decision-making and resilience. Additionally, automation, robotics, and AI in the metaverse can revolutionize how operations work and make complex technologies more accessible.

However, successful transformation in the metaverse also relies on a proactive and adaptable approach, along with a culture of learning and innovation. Organizations must network and collaborate with experts, stay updated on technology trends, and continuously innovate to thrive in the metaverse.

Key Takeaways

- The industrial metaverse combines technologies like digital twins, IoT, AI and ML, VR and AR, advanced networks, and cloud and edge computing to create a digital model of physical operations and revolutionize manufacturing processes.

- Organizations need to embrace change management, have a culture of learning and innovation, and be agile and ready to adopt changing technologies to successfully transform and leverage the industrial metaverse.

- The industrial metaverse enables collaboration, innovation, improved decision-making, and the digital transformation of physical operations, leading to better resilience, agility, supply chain optimization, and cost management.

- SAP's technologies and approaches, such as its metadata management layer and acquisition of LeanIX, contribute to the capabilities and advancements in the industrial metaverse, while organizations also need to consider hybrid cloud migration choices and clear communication for existing on-premises customers.

The Evolution of Manufacturing in the Industrial Metaverse

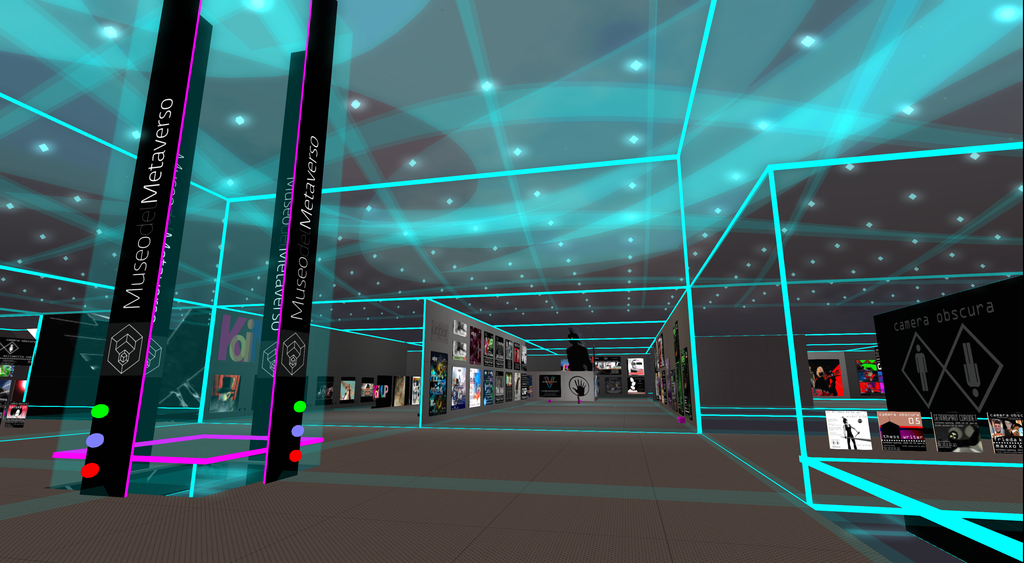

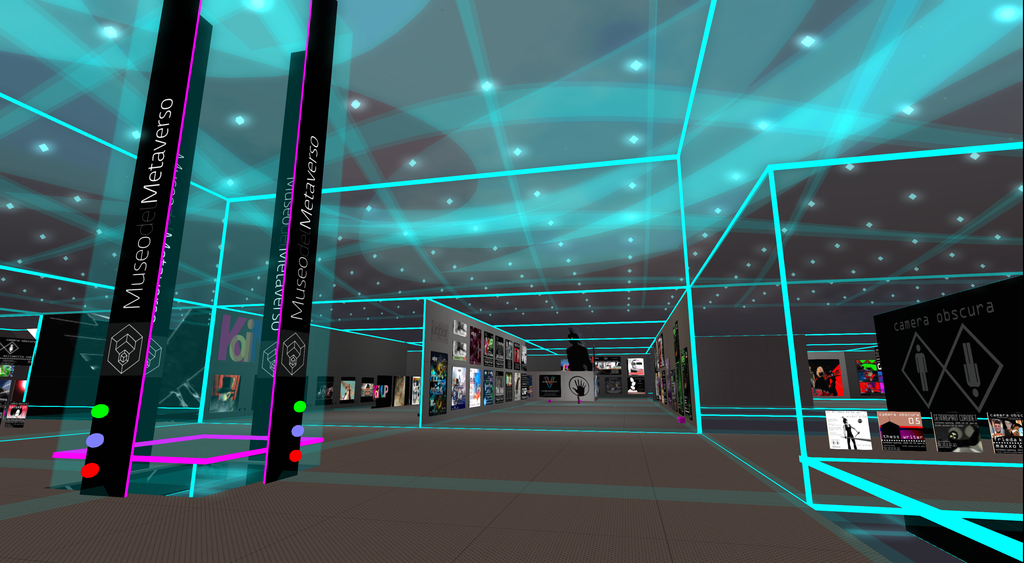

The industrial metaverse is reshaping the manufacturing industry by revolutionizing work processes and introducing innovative solutions. With the integration of technologies like digital twins, IoT, AI and ML, VR and AR, advanced 5G and 6G networks, cloud and edge computing, the metaverse is transforming the way manufacturing operations are conducted. Virtual workspaces such as Virbela and Microsoft Mesh enable efficient collaboration, automation, and analytics-based decision-making, leading to increased productivity and improved outcomes. The metaverse allows organizations to create digital models of their physical operations, enabling better decision-making and resilience. Automation, robotics, and AI within the metaverse have the potential to revolutionize how operations work and make complex technologies more accessible. The industrial metaverse is driving a paradigm shift in the manufacturing industry, offering new possibilities and paving the way for innovative solutions and improved efficiencies.Embracing Digital Twins: A Game-Changer in Manufacturing

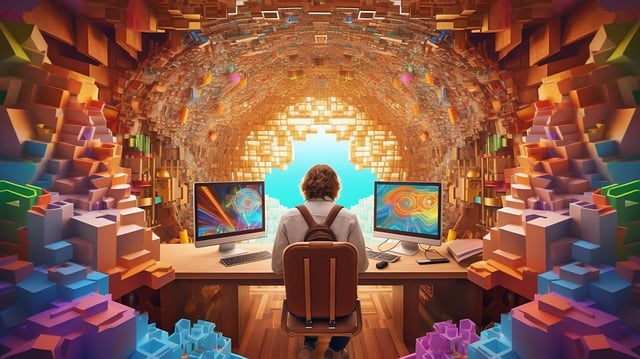

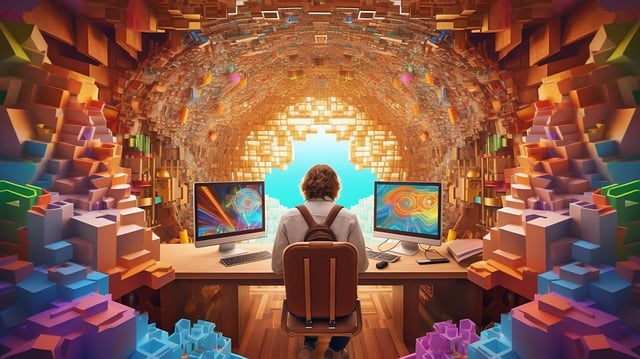

Embracing digital twins in the manufacturing sector has the potential to revolutionize operational efficiency and decision-making processes. A digital twin is a virtual representation of a physical asset or system that enables real-time monitoring, analysis, and optimization. By creating a digital replica of a product or production line, manufacturers can gain valuable insights into performance, identify potential issues, and make data-driven decisions. Digital twins can simulate different scenarios, enabling manufacturers to optimize processes, improve quality, and reduce downtime. Additionally, digital twins can be used throughout the product lifecycle, from design and development to maintenance and customer support.

This technology has the power to transform the manufacturing industry by increasing productivity, reducing costs, and enhancing overall competitiveness. As more companies embrace digital twins, we can expect to see significant advancements in manufacturing processes and outcomes.

Digital twins can simulate different scenarios, enabling manufacturers to optimize processes, improve quality, and reduce downtime. Additionally, digital twins can be used throughout the product lifecycle, from design and development to maintenance and customer support.

This technology has the power to transform the manufacturing industry by increasing productivity, reducing costs, and enhancing overall competitiveness. As more companies embrace digital twins, we can expect to see significant advancements in manufacturing processes and outcomes.

The Power of AI and ML in Industrial Metaverse Manufacturing

AI and ML play a crucial role in driving innovation and optimizing processes in the manufacturing sector within the context of the industrial metaverse. The integration of AI and ML technologies in the industrial metaverse enables manufacturers to automate and improve various aspects of their operations. Through the use of AI algorithms, machines can analyze vast amounts of data and make intelligent decisions in real-time, leading to increased efficiency and productivity. ML algorithms further enhance the capabilities of AI by allowing machines to learn from data and improve their performance over time. This enables manufacturers to achieve higher levels of accuracy and precision in their manufacturing processes, resulting in better product quality and reduced waste. Additionally, AI and ML can help manufacturers predict maintenance needs, optimize supply chain management, and enhance overall decision-making in the manufacturing sector. As the industrial metaverse continues to evolve, AI and ML will continue to play a vital role in revolutionizing the manufacturing industry.Enhancing Collaboration and Decision-Making in the Metaverse

Collaboration and decision-making in the metaverse are enhanced through the integration of advanced technologies and immersive virtual workspaces. The metaverse provides a unique platform for individuals and organizations to come together, regardless of physical location, and work in a virtual environment that simulates real-world interactions. Through technologies like virtual reality (VR) and augmented reality (AR), participants can engage in collaborative discussions, brainstorming sessions, and problem-solving activities. These virtual workspaces offer a range of tools and features that facilitate efficient collaboration, such as real-time communication, file sharing, and interactive 3D models.

Additionally, advanced technologies like artificial intelligence (AI) and machine learning (ML) enable data-driven decision-making in the metaverse, leveraging analytics and predictive algorithms to inform strategic choices.

The integration of these technologies in the metaverse not only enhances productivity but also fosters innovation and creativity in the decision-making process.

Through technologies like virtual reality (VR) and augmented reality (AR), participants can engage in collaborative discussions, brainstorming sessions, and problem-solving activities. These virtual workspaces offer a range of tools and features that facilitate efficient collaboration, such as real-time communication, file sharing, and interactive 3D models.

Additionally, advanced technologies like artificial intelligence (AI) and machine learning (ML) enable data-driven decision-making in the metaverse, leveraging analytics and predictive algorithms to inform strategic choices.

The integration of these technologies in the metaverse not only enhances productivity but also fosters innovation and creativity in the decision-making process.

From Automation to Robotics: Revolutionizing Manufacturing Processes

The integration of automation and robotics in the manufacturing sector is driving significant advancements in operational efficiency and productivity. As technology continues to evolve, manufacturers are embracing automation and robotics to streamline their processes and enhance their capabilities. Automated systems and robots are being used to perform repetitive tasks, such as assembly, packaging, and material handling, with greater precision and speed than human workers. This not only reduces the risk of errors but also increases production output. Additionally, automation and robotics enable manufacturers to optimize their use of resources, minimize waste, and improve overall quality control. By leveraging these technologies, manufacturers can achieve higher levels of efficiency, lower production costs, and ultimately deliver products to market faster. As the manufacturing industry continues to embrace automation and robotics, the potential for further advancements and innovations in this field is immense.The Role of Advanced Networks in the Industrial Metaverse

Advanced networks play a crucial role in enabling seamless connectivity and data transmission within the metaverse, facilitating real-time collaboration and efficient decision-making. As the industrial metaverse continues to evolve and revolutionize manufacturing processes, the need for robust and reliable networks becomes even more critical. These advanced networks, such as 5G and 6G, provide the necessary infrastructure for connecting various devices, sensors, and digital twins, allowing for the seamless exchange of data and information. This connectivity enables real-time monitoring and control of operations, enhancing efficiency and productivity. Additionally, advanced networks support immersive technologies like virtual reality and augmented reality, enabling remote collaboration and knowledge sharing.

With the ability to transmit large volumes of data quickly and securely, advanced networks are instrumental in unlocking the full potential of the industrial metaverse and driving the transformation of the manufacturing industry.

Additionally, advanced networks support immersive technologies like virtual reality and augmented reality, enabling remote collaboration and knowledge sharing.

With the ability to transmit large volumes of data quickly and securely, advanced networks are instrumental in unlocking the full potential of the industrial metaverse and driving the transformation of the manufacturing industry.

Harnessing the Potential of Cloud and Edge Computing in Manufacturing

Cloud and edge computing offer manufacturers the opportunity to leverage scalable and distributed computing resources for enhanced data processing and real-time analytics. Cloud computing provides a centralized platform where manufacturers can store and process large volumes of data, eliminating the need for on-premises infrastructure and reducing costs. It also enables seamless collaboration and data sharing across different locations and teams. On the other hand, edge computing brings computing power closer to the data source, allowing for faster processing and analysis of real-time data. This is particularly beneficial in manufacturing settings where real-time insights are crucial for optimizing operations and improving productivity.The Impact of Virtual Workspaces on Manufacturing Efficiency

Virtual workspaces have significantly improved manufacturing efficiency by enabling seamless collaboration, streamlined communication, and efficient decision-making processes. These virtual workspaces, such as Virbela and Microsoft Mesh, provide a platform for teams to collaborate effectively, regardless of their physical locations. Through virtual reality and augmented reality technologies, employees can interact in a virtual environment that simulates a physical workspace. This allows for real-time collaboration, instant communication, and the ability to share and manipulate digital models of products and processes. By eliminating the need for physical presence, virtual workspaces reduce travel time and costs, increase productivity, and enable teams to make faster and more informed decisions. Additionally, virtual workspaces can integrate with other technologies such as IoT and AI, further enhancing manufacturing efficiency and enabling organizations to adapt to the demands of the modern industry.Creating Resilient Operations in the Industrial Metaverse

The creation of resilient operations in the metaverse requires a strategic focus on leveraging emerging technologies and fostering a culture of adaptability and collaboration. As organizations embrace the industrial metaverse, they must harness the power of technologies like digital twins, IoT, AI and ML, VR and AR, advanced 5G and 6G networks, and cloud and edge computing. These technologies enable organizations to create a digital model of their physical operations, facilitating better decision-making and resilience. Additionally, automation, robotics, and AI in the metaverse can revolutionize how operations work and make complex technologies more accessible.

However, successful transformation in the metaverse also relies on a proactive and adaptable approach, along with a culture of learning and innovation. Organizations must network and collaborate with experts, stay updated on technology trends, and continuously innovate to thrive in the metaverse.

As organizations embrace the industrial metaverse, they must harness the power of technologies like digital twins, IoT, AI and ML, VR and AR, advanced 5G and 6G networks, and cloud and edge computing. These technologies enable organizations to create a digital model of their physical operations, facilitating better decision-making and resilience. Additionally, automation, robotics, and AI in the metaverse can revolutionize how operations work and make complex technologies more accessible.

However, successful transformation in the metaverse also relies on a proactive and adaptable approach, along with a culture of learning and innovation. Organizations must network and collaborate with experts, stay updated on technology trends, and continuously innovate to thrive in the metaverse.